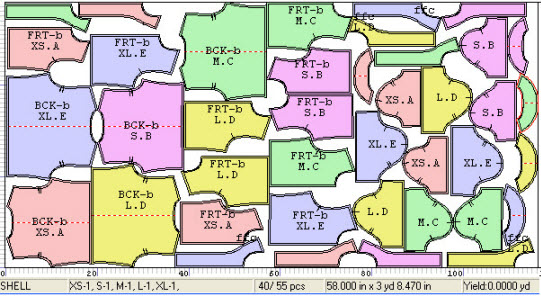

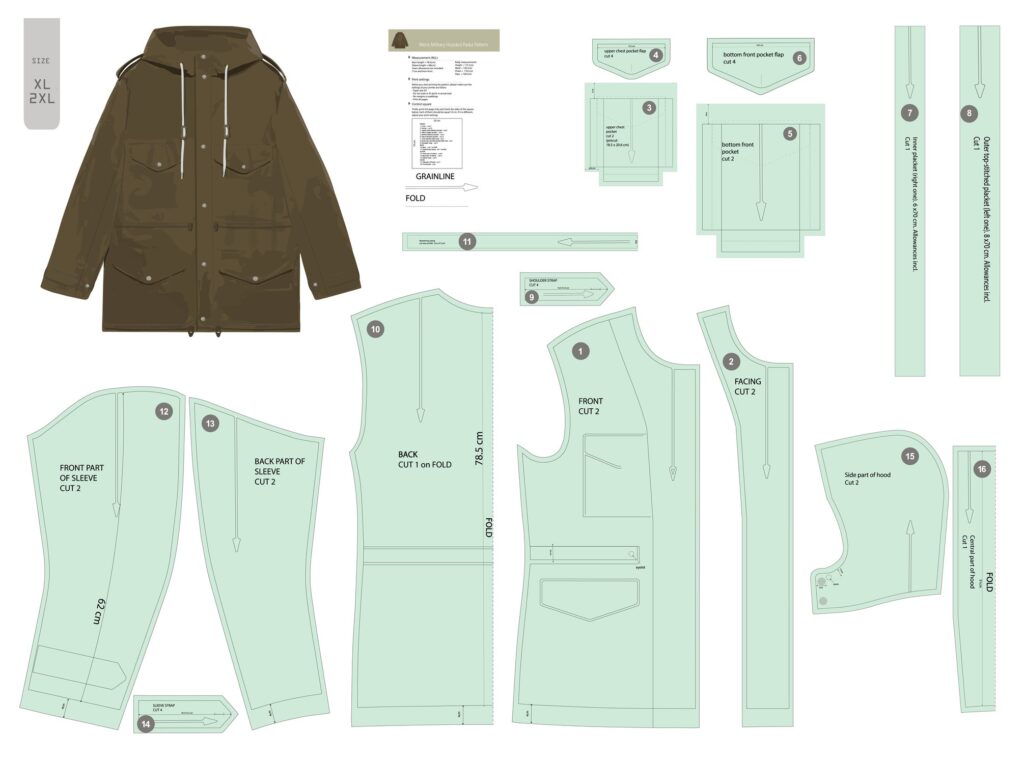

Pattern marker making is the process of arranging graded pattern pieces on fabric in the most efficient layout to minimize waste and optimize material usage. This step is crucial in apparel manufacturing as it directly impacts fabric consumption, production costs, and cutting accuracy.

At Fabinlays, we use advanced CAD software to create precise pattern markers that ensure:

✅ Maximum Fabric Utilization – Reducing material waste and optimizing cost-efficiency.

✅ Accurate Cutting Guidelines – Ensuring smooth production and consistency.

✅ Seamless Manufacturing Process – Helping designers and manufacturers achieve high-quality results with minimal errors.

Pattern marker making plays a crucial role in efficient fabric utilization and cost-effective garment production. Here’s why it’s essential:

✅ Maximizes Fabric Usage – A well-planned marker layout reduces fabric waste, lowering production costs.

✅ Ensures Cutting Accuracy – Properly placed patterns improve cutting precision, leading to consistent garment quality.

✅ Speeds Up Production – Optimized marker layouts streamline the cutting process, saving time and effort.

✅ Reduces Material Costs – By strategically arranging pattern pieces, manufacturers can use fabric more efficiently, minimizing excess waste.

At Fabinlays, we use advanced CAD systems to create highly optimized pattern markers, ensuring efficiency, accuracy, and sustainability in apparel production. 🚀

We create efficient marker layouts to minimize fabric waste and reduce production costs.

Using advanced CAD software, we ensure precise and accurate pattern arrangements.

We tailor marker layouts based on fabric type, garment style, and production requirements.

Our expertly crafted markers enhance cutting efficiency, ensuring smooth and error-free manufacturing.

Absolutely! We tailor marker layouts to match different fabric widths, garment styles, and cutting methods, ensuring optimal efficiency for each project.

By optimizing fabric placement, digital marker making reduces fabric waste, allowing manufacturers to cut more pieces with less material, ultimately lowering production costs.

The turnaround time depends on the complexity of the design and the number of sizes required. At Fabinlays, we ensure fast and accurate grading, typically delivering within a few business days.